|

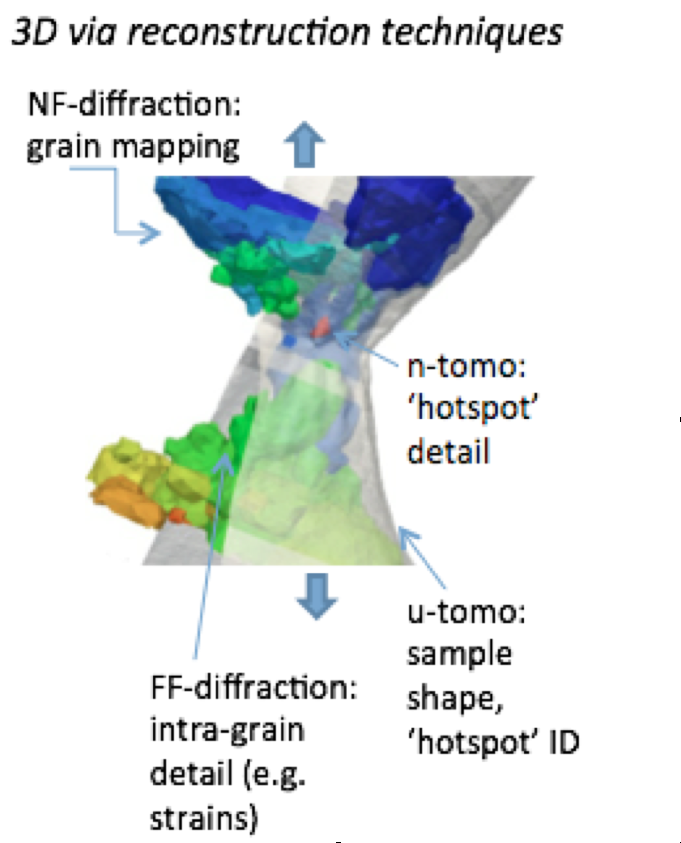

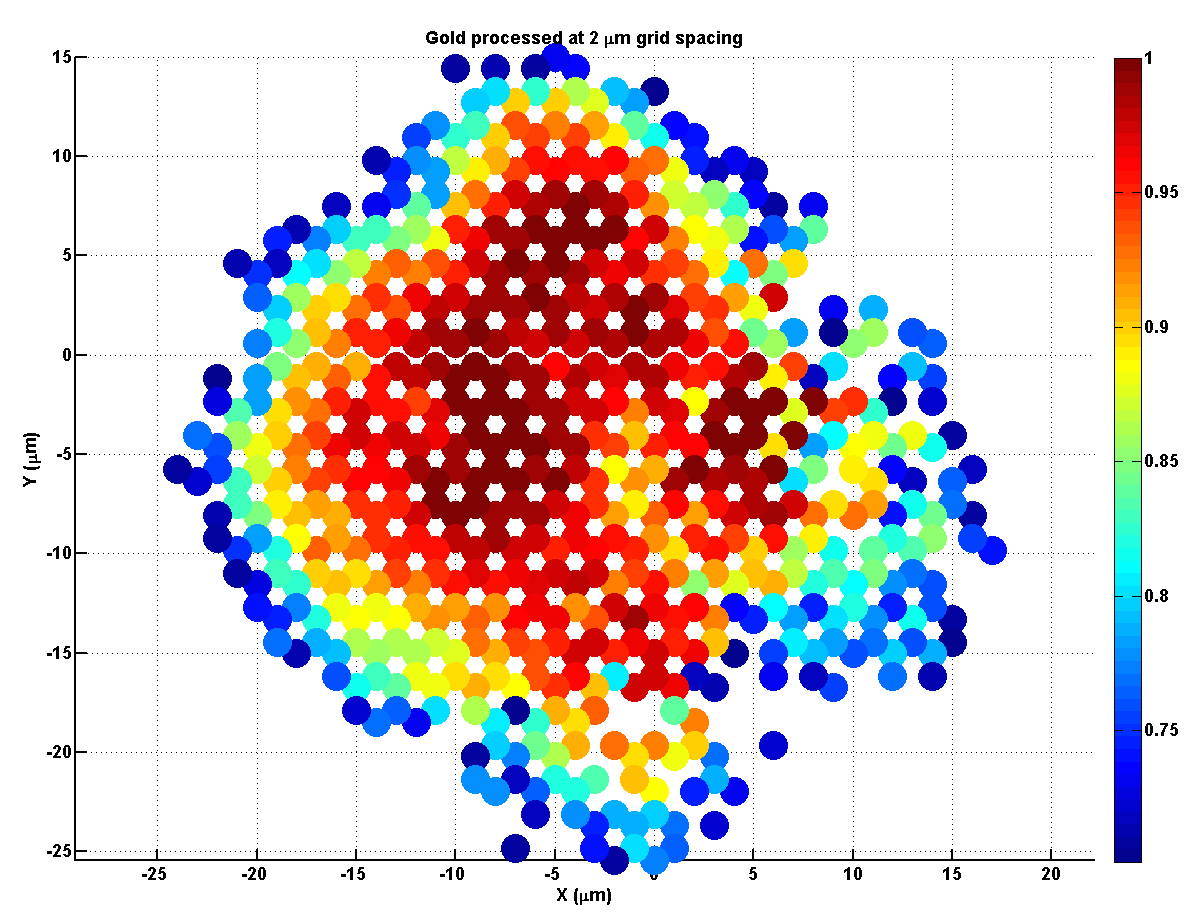

The MIDAS software package allows users to non-destructively image in three dimensions the microstructure, e.g. the interrelationships between the grains, making up crystalline materials.It takes as input x-ray diffraction data from area detectors, collected as a function of rotation about a single axis (omega).The output is a grain-by-grain map of crystallographic parameters in the irradiated volume including lattice parameters, orientations, positions and volumes and, in certain cases, grain shape.Currently only a few synchrotron facilities are available worldwide which can generate this type of diffraction data. The closest non-x-ray analogue is electron-backscatter diffraction, available much more widely, which provides 2D (surface) information with higher spatial resolution but poorer resolution of crystallographic parameters. |

| Distribution & Impact |

|

MIDAS has been used successfully for data analysis by 1-ID users from General Electric Global Research (Yan Gao); ANL-Nuclear Engineering (Meimei Li);Colorado School of Mines (Aaron Stebner) and the University of Illinois (Armand Beaudoin). First scientific paper from MIDAS use: “High-Energy Synchrotron X-ray Techniques for Studying Irradiated Materials”, J.-S. Park et al, Journal of Materials Research (in press). |

| Funding Source |

|

Development for different parts of MIDAS have been supported by General Electric Global Research & the Air Force Research Laboratory as well as operational funding from the APS (contract DE-AC02-06CH11357). HPC porting supported as part of Argonne LDRD "Integrating Simulation and Observation: Discovery Engines for Big Data," Ian T. Foster, PI. |

| Please cite |

|

A publication describing MIDAS is currently in preparation. |

| Related Publications |

| The MIDAS workflow is described in: “Big Data Staging with MPI-IO for Interactive X-ray Science”, J.M. Wozniak, H. Sharma et al, BDC-2014 (accepted).

Background work leading to MIDAS are described in: H. Sharma, R.M. Huizenga and S.E. Offerman: A fast methodology to determine the characteristics of thousands of grains using three-dimensional X-ray diffraction. I. Overlapping diffraction peaks and parameters of the experimental setup Journal of Applied Crystallography. 45, 693 (2012). H. Sharma, R.M. Huizenga and S.E. Offerman: A fast methodology to determine the characteristics of thousands of grains using three-dimensional X-ray diffraction. II. Volume, centre-of-mass position, crystallographic orientation and strain state of grains Journal of Applied Crystallography. 45, 705 (2012). The first scientific paper to employ MIDAS results: “High-Energy Synchrotron X-ray Techniques for Studying Irradiated Materials”, J.-S. Park et al, Journal of Materials Research (in press). |

| Additional Development Goals |

|

|

MIDAS V1 is installed on the APS cluster for 1-ID users and installation on the Argonne internal (LCRC) cluster is being pursued. Distribution of code will be considered once a stable release is complete and with more experience is gained in use of the software.

MIDAS V1 is installed on the APS cluster for 1-ID users and installation on the Argonne internal (LCRC) cluster is being pursued. Distribution of code will be considered once a stable release is complete and with more experience is gained in use of the software. Over the next year or so, the following enhancements are planned:

Over the next year or so, the following enhancements are planned: